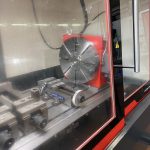

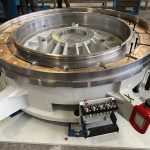

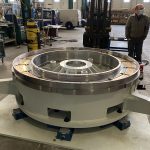

Assembly and installation of rotary tables.

Thanks to our knowledge of control machine tools, companies such as Multimatic on behalf of Lehamnn, Vega International Tool on behalf of Nikken, Poletti, Hiwin, Meccanica Scotti, Euroma, Ucam, Ganro have entrusted us the installations on hundreds of working stations. Installation means mechanical assembly and alignment, electrical connection to the cabinet and to the CNC, parameterization and testing.

Electric and electronic assistance.

After 32 years of service, there has been a lot of electronic… From the rack-mounted “ancient siemens cards”, to the Indramat, Servomac drives, we have reached the digital era. Siemens, Heidenhain, Fanuc drives are our bread and butter. We carry out repairs (if possible) or replacements and exchanges. We manage several series of ready-to-use drives within a MODULA warehouse.

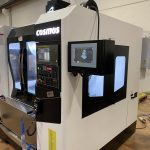

Assistance on large machining centers

With CNC machine tools with moving column or gantry and workbenches from 3 to 30 meters, we have the possibility to perform installation, leveling, cartesian geometries on the axes through granite lines and squares, digital electronic level, interferometric laser geometric laser. Revision of orthogonal heads (tilting rotary axes), Geometric control of the Tool Center Point (TCP). Kinematic.

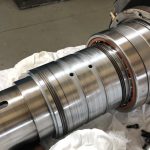

Assistance on spindles.

Revision of spindles for CNC lathes and for machining center. Replacement bearings, reparation of water or oil leaks. Geometrical alignment between spindle and axes.

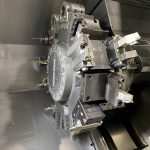

Assistance on turning.

Geometrical alignment between axes and turret.

Geometrical alignment on the tool holder of the turret.

Electric and mechanical revision of the tool carrier. We are specialized in Baruffaldi and Duplomatic. Internal testing of the turret with electronic rotation and cycle control bench.

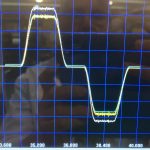

Installation of interface system for l4.0.

SeA tech, in collaboration with Romagna Servizi (Confindustria), CNI and Botika, has developed a CNC machine supervision system with a system called MDC (Machine Data Collector), then renamed S.A.M. The system interacts with the CNC, drawing all the digital data necessary for the supervision of the system through a Mes software installed on board the MDC and transfers them to the company management system. We control the active program, the number of pieces to perform, the total number of finished pieces, the total cycle time, the time taken per piece, the machine set-up time, the changing time of the piece, all the motor currents of the axes and spindles (absorption in Ampere or in %) monitoring the efforts. We control the motor temperatures, the bearing temperatures on the axes and spindles, the vibration of the axes and spindles or any collisions, also providing data for predictive maintenance. The system also interacts with the web by sending alarm signals or anomalies directly to your mobile phone.